What is the chemical composition of Babbitt alloy

Abstract: What is the chemical composition of Babbitt alloy?

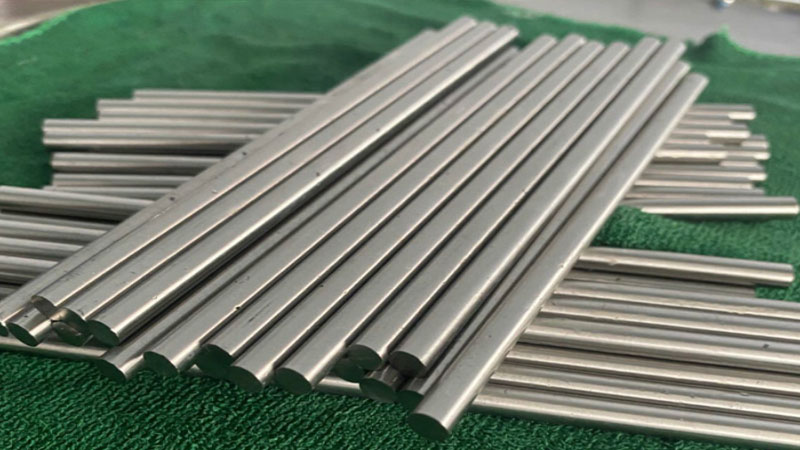

Babbitt alloy, also known as white metal, is a type of soft metal used in the manufacturing of bearings. It has excellent characteristics such as low friction and high load capacity, making it popular in industries such as automotive and machinery. In this article, we will delve into the chemical composition of Babbitt alloy, exploring its key components and their roles in enhancing the performance of this important material.

1. Overview of Babbitt Alloy Composition

Babbitt alloy is primarily composed of three main elements: tin, antimony, and copper. Each of these elements plays a crucial role in determining the properties and functionality of the alloy. The combination of these elements creates a unique structure that allows Babbitt alloy to withstand heavy loads, reduce friction, and provide superior performance in various applications.

1.1 Tin in Babbitt Alloy

Tin is the primary component of Babbitt alloy and typically constitutes the major portion of its composition. It forms a matrix that holds the other alloying elements in place, providing stability and structural strength to the material. Tin also contributes to the low friction properties of Babbitt alloy, reducing wear and extending the lifespan of bearings and other components.

1.2 Antimony in Babbitt Alloy

Antimony is another essential element in Babbitt alloy, often found in smaller quantities compared to tin. It acts as a hardener, enhancing the alloy's strength and wear resistance. The presence of antimony also improves the material's ability to withstand high temperatures, making it suitable for demanding applications that involve extreme conditions.

1.3 Copper in Babbitt Alloy

Copper is a minor component of Babbitt alloy, but its inclusion is crucial for optimal performance. Copper improves the thermal conductivity of the material, facilitating heat dissipation and preventing overheating. It also contributes to the overall strength and toughness of the alloy, ensuring its ability to withstand heavy loads and shocks.

2. The Role of Other Alloying Elements

In addition to tin, antimony, and copper, Babbitt alloy may include trace amounts  of other elements to further enhance its properties. These additional alloying elements may include lead, arsenic, or zinc, among others. While their presence is typically minimal, they can significantly impact the material's performance in specific applications.

of other elements to further enhance its properties. These additional alloying elements may include lead, arsenic, or zinc, among others. While their presence is typically minimal, they can significantly impact the material's performance in specific applications.

2.1 Lead in Babbitt Alloy

Lead is sometimes added to Babbitt alloy to improve its conformability. This means that it can easily adapt to the shape of the mating surfaces, filling in gaps and reducing friction. However, due to environmental considerations and health concerns, the use of lead in Babbitt alloy has decreased over time, with alternative additives being sought.

2.2 Arsenic in Babbitt Alloy

Arsenic is occasionally present in Babbitt alloy, primarily for its ability to impede corrosion. It helps protect the bearing surfaces from degradation, ensuring their longevity and reducing maintenance requirements. However, similar to lead, the use of arsenic has become less common due to its toxic nature, and alternative corrosion inhibitors are being explored.

2.3 Zinc in Babbitt Alloy

Zinc is another element that can be found in Babbitt alloy, serving as a grain refiner. It aids in the formation of a fine-grained structure, which improves the material's overall strength and wear resistance. The addition of zinc can help optimize the performance of Babbitt alloy, particularly in applications where high loads and vibrations are present.

3. Conclusion

In conclusion, Babbitt alloy is a specialized material that offers exceptional properties for bearing applications. Its chemical composition, primarily consisting of tin, antimony, and copper, forms the foundation for its desirable characteristics such as low friction, high load capacity, and temperature resistance. Additional alloying elements like lead, arsenic, and zinc can further enhance specific aspects of the alloy's performance. Understanding the chemical composition of Babbitt alloy is essential for manufacturers, engineers, and researchers to optimize its use and explore potential advancements in this vital material.

Write a Comment