Nickel Alloy and Copper Soldering Methods

NiAl and Cu soldering methods have significant applications in various industries due to their unique properties and advantages. This article aims to provide an in-depth understanding of these soldering methods, focusing on four aspects: composition and properties of Nickel Alloy and Copper; soldering techniques and processes; applications in different industries; and future research directions.

1. Composition and Properties  of Nickel Alloy and Copper

of Nickel Alloy and Copper

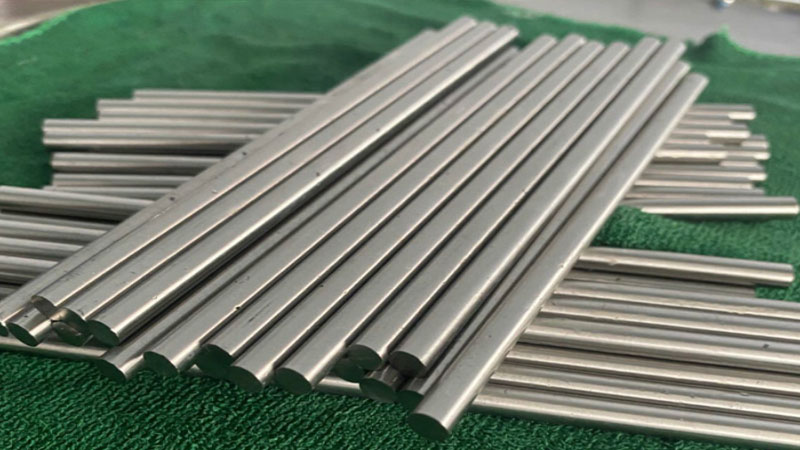

Nickel alloys are metallic compounds composed of nickel as the base metal and other elements to enhance specific properties. These alloys exhibit excellent corrosion resistance, high-temperature strength, and good mechanical properties, making them ideal for applications in aerospace, chemical, and marine industries. On the other hand, copper possesses exceptional thermal and electrical conductivity, making it a preferred choice for electrical and electronics industries.

2. Soldering Techniques and Processes

2.1 Torch Soldering

Torch soldering is a widely used method that employs a torch flame to heat the solder and the joint. The solder, typically in the form of a wire or bar, is melted and flowed onto the joint, forming a strong bond once cooled. This method requires skill and expertise to ensure proper heating and flux application.

2.2 Induction Soldering

Induction soldering relies on the principle of electromagnetic induction to generate heat in the joint area. An alternating current is passed through a coil, creating a magnetic field that induces eddy currents and generates localized heating. This technique offers precise control over the heating process and is commonly used in the automotive and electronic industries.

2.3 Furnace Soldering

Furnace soldering involves heating the entire assembly in a controlled atmosphere or vacuum furnace. The solder material, either in the form of a wire or paste, is applied to the joints, and the assembly is heated to the solder's melting temperature. This method provides uniform heating and is suitable for large-scale production.

3. Applications in Different Industries

3.1 Aerospace Industry

Nickel alloys and copper soldering methods find extensive applications in the aerospace industry for joining critical components such as turbine blades, fuel systems, and engine parts. The high-temperature strength and corrosion resistance of nickel alloys ensure reliable performance in extreme environments, while copper soldering provides efficient electrical connections.

3.2 Electronics Industry

In the electronics industry, copper soldering techniques are essential for reliable connections in printed circuit boards, electronic components, and wire bonding. The exceptional electrical conductivity of copper ensures low resistance connections, while various copper alloys offer enhanced mechanical strength and thermal stability.

3.3 Automotive Industry

The automotive industry requires robust soldering methods to join various components, such as heat exchangers, radiators, and exhaust systems. Nickel alloys are often used due to their high-temperature resistance and corrosion properties, while copper soldering methods ensure efficient heat transfer and electrical connectivity.

4. Future Research Directions

Despite the significant advancements in nickel alloy and copper soldering methods, several research directions offer potential for further improvements. These include the development of high-temperature solder materials, exploration of new flux compositions, optimization of soldering parameters, and investigation of alternative joining techniques such as laser welding and diffusion bonding.

In conclusion, nickel alloy and copper soldering methods play crucial roles in various industries, providing reliable and efficient joining solutions. The composition and properties of these materials, along with the different soldering techniques, determine their suitability for specific applications. Future research should focus on addressing current challenges and exploring innovative approaches to enhance the performance of these soldering methods. By understanding and advancing these techniques, industries can continue to benefit from the unique properties of nickel alloys and copper.

Write a Comment