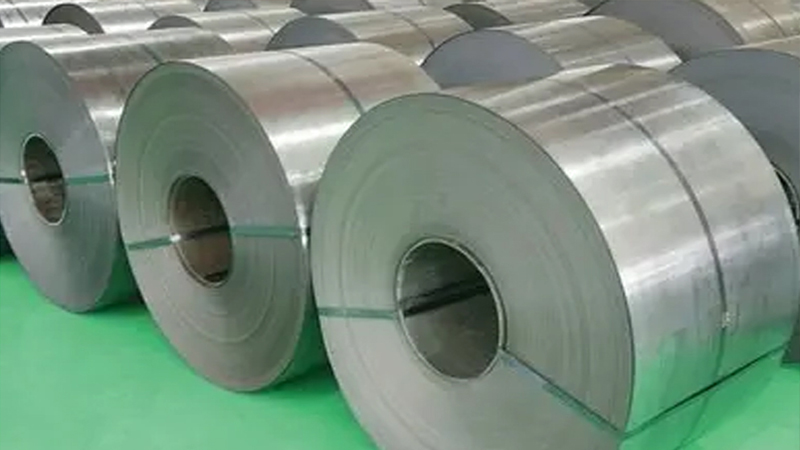

Nickel alloy plate

Nickel Alloy Plate: A Comprehensive Guide

Abstract:

Nickel alloy plate plays a crucial role in various industries due to its unique properties and versatility. This article aims to provide a comprehensive understanding of nickel alloy plate, including its composition, manufacturing process, applications, and future prospects. By examining these aspects in detail, readers will gain insights into the significance and potential of nickel alloy plate in modern industrial applications.

1. Composition and Properties of Nickel Alloy Plate

Nickel alloy plate is primarily composed of nickel, along with other alloying elements such as chromium, molybdenum, and titanium. The precise composition determines the specific properties exhibited by the plate. This section explores the influence of these alloying elements on the mechanical, thermal, and corrosion resistance properties of nickel alloy plate. By understanding the composition-property relationship, engineers and manufacturers can tailor the material to meet specific application requirements.

2. Manufacturing Process of Nickel Alloy Plate

The manufacturing process of nickel alloy plate involves various steps, including melting, casting, rolling, and heat treatment. Each step significantly affects the final quality and performance of the plate. This section provides a comprehensive overview of each manufacturing step, highlighting the key parameters, challenges, and advancements in the process. By optimizing the manufacturing process, engineers can enhance the mechanical properties and structural integrity of nickel alloy plate.

3. Applications of Nickel Alloy Plate

Nickel alloy plate finds extensive applications in diverse industries such as aerospace, chemical processing, power generation, and marine engineering. This section explores these applications in detail, showcasing the unique advantages of nickel alloy plate over other materials. From aircraft components to offshore oil platforms, nickel  alloy plate demonstrates superior resistance to corrosion, high temperature, and mechanical stress. Case studies and practical examples further illustrate the successful utilization of nickel alloy plate in real-world scenarios.

alloy plate demonstrates superior resistance to corrosion, high temperature, and mechanical stress. Case studies and practical examples further illustrate the successful utilization of nickel alloy plate in real-world scenarios.

4. Future Prospects and Innovations in Nickel Alloy Plate

As technology advances, continuous research and development efforts are being made to improve the performance and expand the applications of nickel alloy plate. This section discusses the latest innovations, emerging trends, and future prospects of nickel alloy plate. From nanostructured alloys to additive manufacturing techniques, researchers are exploring new avenues to enhance the properties and cost-effectiveness of nickel alloy plate. Moreover, the integration of nickel alloy plate with other materials opens up possibilities for advanced composites with exceptional properties.

V. Conclusion:

In conclusion, nickel alloy plate is a vital material in modern industries, owing to its unique combination of properties and versatility. This article provides a comprehensive overview of the composition, manufacturing process, applications, and future prospects of nickel alloy plate. By understanding the intricacies of this material, engineers, researchers, and manufacturers can harness its full potential to drive innovation and overcome challenges in various industrial sectors. The continuous advancements in nickel alloy plate technology promise a brighter future with enhanced performance and novel applications. It is imperative to continue exploring this field through collaborative research and development initiatives, thereby unlocking new possibilities for industrial progress.

Write a Comment