Zinc-nickel alloy plating effect is not good

Abstract:

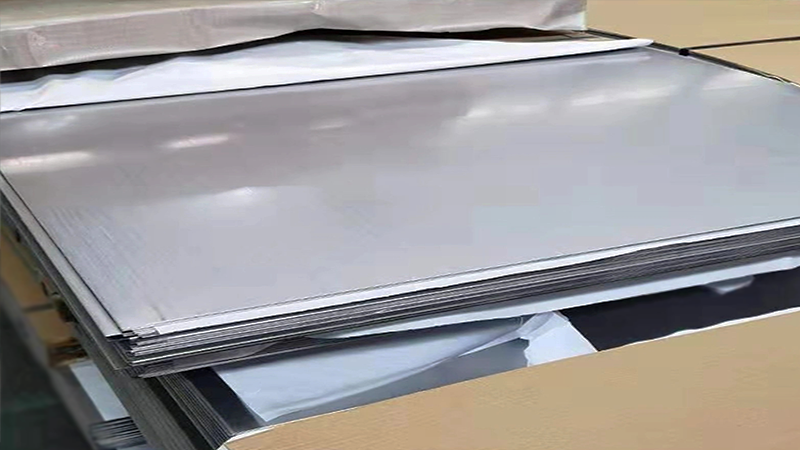

Zinc-nickel alloy plating is widely used in various industries due to its excellent corrosion resistance. However, some instances have shown that the plating effect of zinc-nickel alloy is not satisfactory. This article aims to explore the reasons behind this issue and discuss potential solutions. The background information of zinc-nickel alloy plating will also be provided to familiarize readers with the topic.

Text:

1. Composition of Zinc-Nickel Alloy Plating

Zinc-nickel alloy plating is typically composed of a mixture of zinc and nickel, with varying proportions of each metal. The plating process involves the deposition of this alloy onto the surface of the substrate. This section will delve into the composition of zinc-nickel alloy, highlighting the role of zinc and nickel in achieving desired properties.

2. Factors Affecting Plating Effect

2.1 Substrate Preparation

Thorough substrate preparation is crucial for achieving a satisfactory plating effect. This includes  removing contaminants, such as grease and oxide layers, from the surface of the substrate. The first subsection will examine the impact of substrate preparation on zinc-nickel alloy plating and discuss potential issues that may arise if this step is not executed properly.

removing contaminants, such as grease and oxide layers, from the surface of the substrate. The first subsection will examine the impact of substrate preparation on zinc-nickel alloy plating and discuss potential issues that may arise if this step is not executed properly.

2.2 Bath Chemistry

The chemical composition of the plating bath greatly influences the plating effect of zinc-nickel alloy. The second subsection will discuss the significance of bath chemistry, particularly focusing on the concentration levels of zinc and nickel ions. It will also explore the importance of maintaining the optimal pH and temperature for the plating process.

2.3 Plating Parameters

Various parameters, such as current density, plating time, and agitation, play a vital role in achieving a desirable plating effect. This subsection will analyze the impact of these parameters on zinc-nickel alloy plating and highlight the challenges associated with improper control or deviation from recommended values.

2.4 Post-Plating Treatment

Post-plating treatment is essential for enhancing the properties and durability of zinc-nickel alloy coatings. This subsection will discuss the significance of post-plating processes, such as passivation and sealing, in improving the overall plating effect. It will also address potential issues that may arise if these treatments are neglected or performed incorrectly.

3. Possible Solutions to Enhance Plating Effect

3.1 Optimization of Plating Process

To improve the plating effect of zinc-nickel alloy, it is essential to optimize the plating process. This subsection will discuss various strategies, such as modifying bath chemistry, optimizing plating parameters, and implementing advanced techniques like pulse plating, to enhance the plating quality.

3.2 Surface Pre-Treatment Methods

Proper surface pre-treatment methods can significantly impact the plating effect. This subsection will explore different surface pre-treatment techniques, such as acid pickling, alkaline cleaning, and electrocleaning, and their potential contributions to achieving a superior plating outcome.

3.3 Surface Analysis and Quality Control

To ensure a satisfactory plating effect, comprehensive surface analysis and quality control measures are necessary. This subsection will discuss the importance of techniques like X-ray diffraction, SEM-EDS analysis, and adhesion testing in evaluating the quality of zinc-nickel alloy plating. It will also highlight the significance of regular quality control checks during the plating process.

Conclusion:

In conclusion, the plating effect of zinc-nickel alloy can be influenced by various factors, including substrate preparation, bath chemistry, plating parameters, and post-plating treatment. Understanding these factors and implementing appropriate solutions can help enhance the plating effect. It is crucial to optimize the plating process, utilize suitable surface pre-treatment methods, and employ thorough surface analysis and quality control measures. By addressing these aspects, the industry can overcome the challenges associated with zinc-nickel alloy plating and achieve improved and consistent results.

Write a Comment