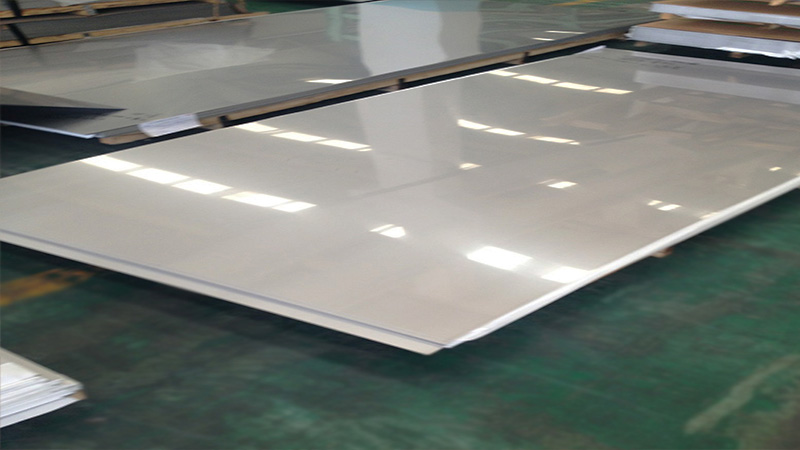

Gr2 Titanium alloy plate

Gr.2 exhibits superior corrosion resistance from high oxidation to low chloride environments. Continuous operation at 800°F and intermittent operation at 1000°F. Production process: Annealed at 1200-1450°F for 15 min to 2 h, air-cooled. Release pressure at 900-1100°F for 30 minutes. Titanium GR 1, 2, 3, and 4 cannot be strengthened by heat treatment.

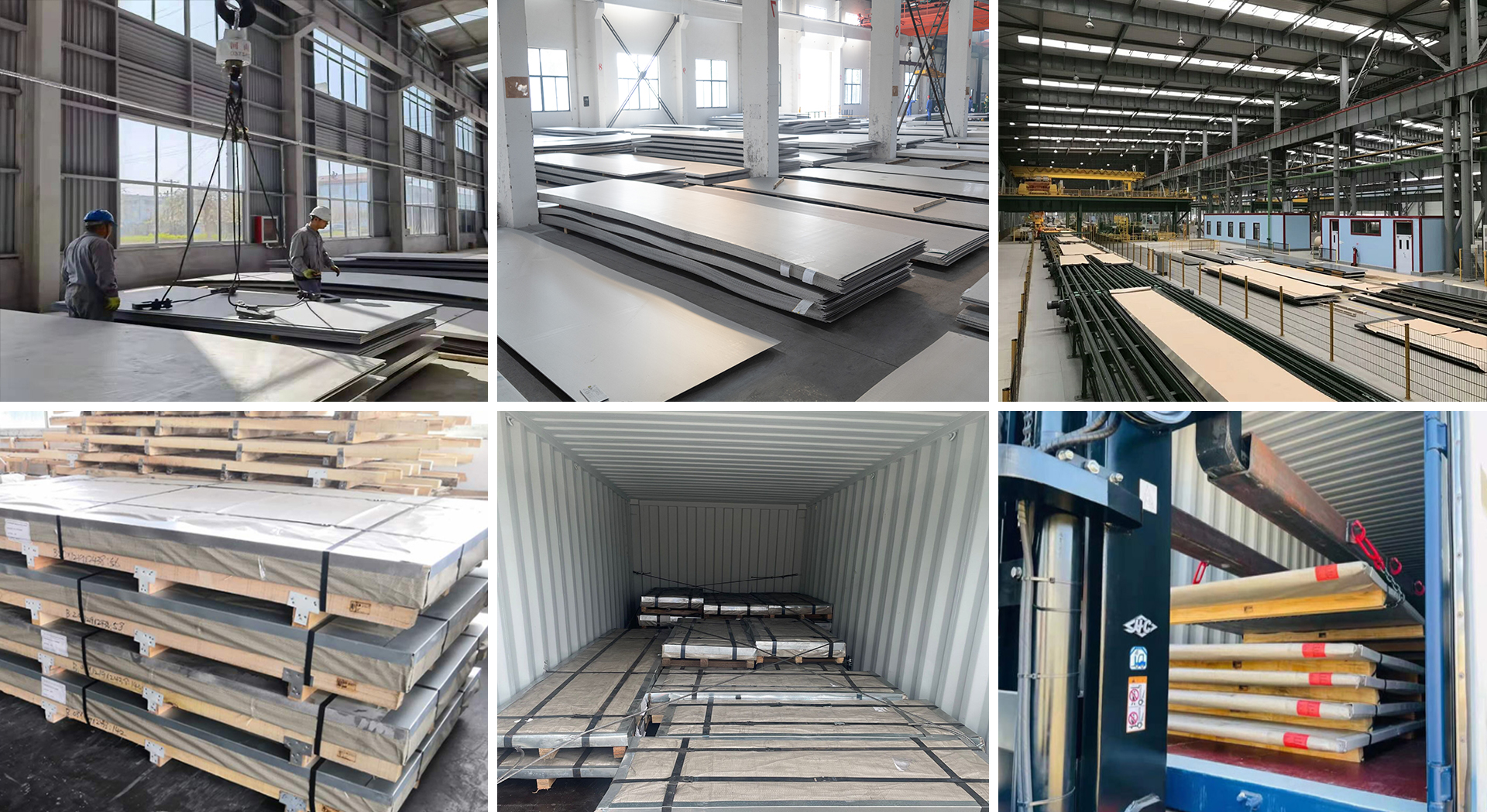

We have been one of the largest and well-known suppliers to the steel industry. HANHUANG has long been committed to the development of alloys and other special steels. Innovation platforms such as the key Laboratory of Advanced Alloys, the National Laboratory of Physics and Chemistry, the Alloy Engineering and Technology Research Center, and the Railway Rolling stock Steel Structure Engineering and Technology Research Center have been established.

We always adhere to the "customer benefit maximization" service purpose, create maximum value for customers. Warmly welcome customers at home and abroad to visit and consult, and sincerely look forward to working with you to create a better future

When alloying elements are added to steel, iron and carbon, the basic components of steel, interact with alloying elements. The purpose of steel alloying is to improve the microstructure and properties of steel by the interaction of alloying elements with iron and carbon and the influence on the phase diagram of iron and carbon and the heat treatment of steel.

Write a Comment