Nickel alloy plating utensils

Nickel Alloy Plating Utensils

Abstract:

Nickel alloy plating utensils have gained significant attention in recent years due to their unique properties and potential applications in various industries. This article aims to explore the characteristics and benefits of nickel alloy plating utensils from different perspectives. By analyzing the composition, manufacturing process, and potential uses of these utensils, we can gain a comprehensive understanding of their advantages and challenges. This article serves as a valuable resource for professionals and enthusiasts interested in the field of nickel alloy plating utensils.

I. Introduction:

Nickel alloy plating utensils have become increasingly popular in various industries, from kitchenware to industrial applications. This introduction will provide background information regarding the importance of utensils in our daily lives, and the need for advanced materials to enhance their performance. By highlighting the significance of nickel alloy plating utensils, we create an engaging context for readers  to explore the following sections.

to explore the following sections.

II. Composition and Manufacturing Process:

2.1 Composition of Nickel Alloy Plating Utensils:

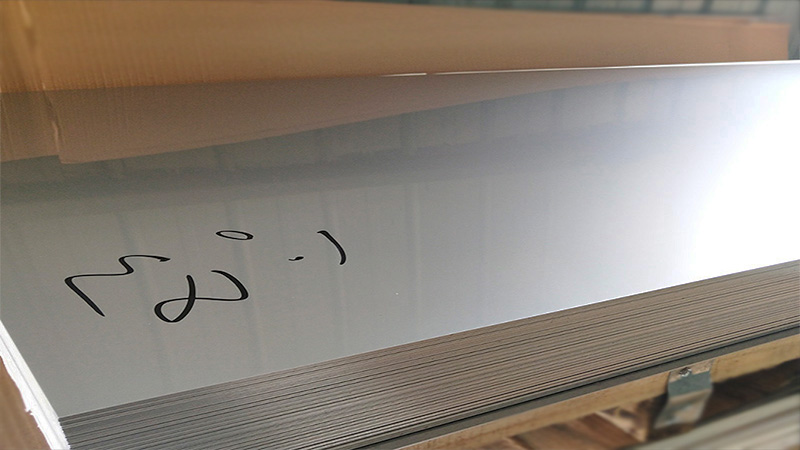

Nickel alloy plating utensils are primarily composed of a combination of nickel and other materials. This section will delve into the different alloys commonly used in plating utensils, such as nickel-chromium, nickel-copper, and nickel-iron. By understanding the specific compositions of these alloys, we can comprehend the unique properties they offer and their relevance to different applications.

2.2 Manufacturing Process of Nickel Alloy Plating Utensils:

This section will detail the manufacturing process involved in producing nickel alloy plating utensils. From the initial preparation of the base material to the plating process, we will explore the steps and techniques utilized. Additionally, we will discuss the importance of quality control measures and the impact they have on the final product. By elucidating the manufacturing process, readers can gain insight into the intricacies of producing these specialized utensils.

III. Applications and Benefits:

3.1 Kitchenware:

One significant application of nickel alloy plating utensils is in the kitchenware industry. This section will highlight the advantages of using these utensils in food preparation, cooking, and serving. By examining the enhanced durability, corrosion resistance, and heat conductivity properties of nickel alloy plating utensils, we can understand why they have become a popular choice among professional chefs and home cooks alike.

3.2 Industrial Uses:

Apart from kitchenware, nickel alloy plating utensils also find essential applications in various industrial sectors. This section will explore the role of these utensils in industries such as aerospace, automotive, and electronics. By focusing on their unique properties, including resistance to high temperatures, wear, and chemical corrosion, we can underline the importance of nickel alloy plating utensils in these demanding environments.

3.3 Medical and Healthcare:

Another area where nickel alloy plating utensils have garnered attention is in the medical and healthcare field. This section will discuss the potential uses of these utensils in surgical instruments, implants, and dental tools. By emphasizing their biocompatibility, sterilization capabilities, and corrosion resistance, we can highlight the advantages they offer in promoting hygiene, patient safety, and overall medical advancements.

IV. Challenges and Future Developments:

4.1 Environmental Considerations:

While nickel alloy plating utensils offer numerous benefits, it is essential to address potential environmental concerns associated with their manufacturing process and disposal. This section will examine the impact of nickel mining, waste management, and recycling methods. By discussing ongoing research and developments in eco-friendly manufacturing and disposal techniques, we can pave the way for sustainable advancements in the field.

4.2 Advancements in Nickel Alloy Plating Techniques:

This section will discuss recent advancements in nickel alloy plating techniques, such as electroless nickel plating and pulse plating. By exploring these innovative methods, we can anticipate improvements in the quality, efficiency, and cost-effectiveness of nickel alloy plating utensils. Furthermore, we will look into emerging technologies that aim to enhance the properties and applications of these utensils.

V. Conclusion:

In conclusion, nickel alloy plating utensils exhibit exceptional properties that make them desirable in a diverse range of applications. From kitchenware to healthcare and industrial sectors, the unique features of these utensils offer numerous benefits to users. However, it is crucial to address environmental concerns and continue research and development efforts to ensure sustainable and innovative advancements in nickel alloy plating utensils. By understanding their composition, manufacturing process, and potential uses, we can appreciate the significant contributions of these utensils in various industries.

Write a Comment