Cast Nickel Alloy 718

Cast Nickel Alloy 718

Abstract:

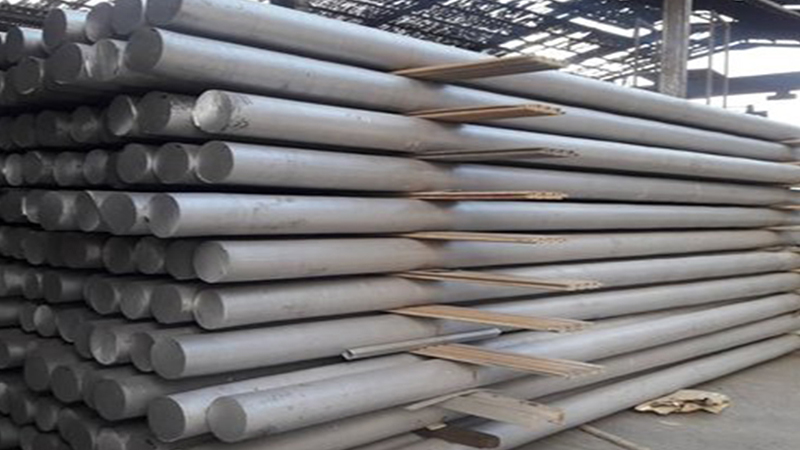

Cast Nickel Alloy 718 is a high-strength, corrosion-resistant alloy that is widely used in various industries. This article provides an in-depth analysis of this alloy, exploring its composition, properties, processing methods, and applications. By delving into the details of Cast Nickel Alloy 718, readers will gain a comprehensive understanding of its significance and potential.

1. Composition and Structure

1.1 Chemical Composition

Nickel Alloy 718 primarily consists of nickel, chromium, and molybdenum, with smaller amounts of other elements such as iron, niobium, and tantalum. The precise composition of the alloy plays a crucial role in determining its properties and performance.

1.2 Microstructure

The microstructure of Cast Nickel Alloy 718 is predominantly a gamma prime (γ') phase, which contributes to its exceptional strength and creep resistance. A comprehensive analysis of the microstructure sheds light on the alloy's mechanical properties and its ability to withstand high temperatures.

1.3 Heat Treatment

Heat treatment is a critical step in optimizing the properties of Cast Nickel Alloy 718. By carefully controlling the temperature and duration of heat treatment, it is possible to achieve desired microstructural changes and enhance the alloy's mechanical performance.

2. Properties and Performance

2.1 Mechanical Properties

Cast Nickel Alloy 718 exhibits impressive mechanical properties, including high tensile strength, excellent fatigue resistance, and remarkable toughness. A thorough examination of these properties provides insights into the alloy's suitability for various demanding applications.

2.2 Corrosion Resistance

One of the standout characteristics of Cast Nickel Alloy 718 is its exceptional resistance to corrosion in harsh environments, including those with high temperatures and corrosive chemicals. This section delves into the corrosion resistance mechanisms of the alloy and discusses its performance in different corrosive conditions.

2.3 High-Temperature Performance

Cast Nickel Alloy 718 demonstrates remarkable stability and integrity when exposed to extreme temperatures. This aspect is particularly crucial in industries such as aerospace and power generation, where components operate under severe thermal conditions.

3. Processing Methods

3.1 Casting Techniques

Casting is a widely used method for fabricating components made of Cast Nickel Alloy 718. This section explores the various casting techniques employed, including investment casting, sand casting, and  centrifugal casting, highlighting their advantages and limitations.

centrifugal casting, highlighting their advantages and limitations.

3.2 Machining and Forming

The machinability and formability of Cast Nickel Alloy 718 are key considerations during its production. Different machining and forming techniques are discussed, along with recommendations for achieving optimal results while minimizing material waste.

3.3 Welding and Joining

Joining Cast Nickel Alloy 718 components through welding is a common practice. However, due to the alloy's unique characteristics, specific welding processes and precautions need to be followed to ensure the integrity and strength of the joints. This section provides an overview of welding methods suitable for this alloy.

4. Applications

4.1 Aerospace Industry

The aerospace industry extensively utilizes Cast Nickel Alloy 718 due to its exceptional strength and resistance to high-temperature environments. This section explores its applications in aircraft engines, gas turbine components, and other critical aerospace assemblies.

4.2 Oil and Gas Sector

The oil and gas sector heavily relies on Cast Nickel Alloy 718 for its resistance to corrosive environments and high-strength requirements. This segment discusses its application in downhole tools, wellheads, and other demanding oil and gas applications.

4.3 Power Generation

Cast Nickel Alloy 718 plays an essential role in power generation systems, where it is used in gas turbine components, nuclear reactors, and other high-temperature applications. This section examines its use in power generation and the advantages it brings to these critical facilities.

Conclusion:

In conclusion, Cast Nickel Alloy 718 is a versatile alloy with exceptional properties and performance. Its composition, microstructure, properties, and processing methods all contribute to its wide-ranging applications in aerospace, oil and gas, and power generation. Understanding the complexities of this alloy is crucial for maximizing its potential and advancing future research in materials science and engineering. Continued investigation and innovation in this field will undoubtedly yield improvements in the alloy's performance and expand its application areas.

Write a Comment